Downward pressure on prices is an ever-present challenge in the food and beverage industry. Business leaders struggle to maintain their margins when the market simply will not bear a price increase.

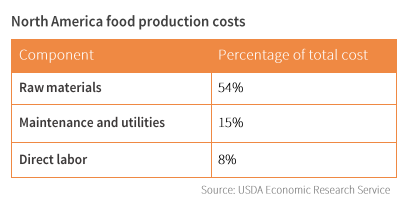

The natural first instinct is to cut costs, and cost-cutting efforts usually begin where the costs are most visible and obvious: labor. Unfortunately, managers often fail to realize that labor accounts for only a small percentage of their overall costs, so even the most aggressive labor cuts make only a commensurately small contribution to overall cost savings.

While laying off workers is both technically (if not emotionally) easy to do and easy to see, the most significant opportunities for cost savings lie elsewhere.

A whitepaper we recently published provides some actionable insight for food and beverage industry leaders who want to make a real impact on reducing costs rather than the mere appearance of it.

Managing shelf lives, expiry dates, recipes, reporting and maintenance all have roles to play, often in ways that aren’t immediately intuitive or obvious. For example, better management of your ingredients can extend shelf life by making sure that soon-to-expire ingredients are used to produce products whose shelf lives are less critical. Similarly, intelligent maintenance scheduling can reduce production interruptions just by taking the big picture into account when scheduling downtime.

The key to uncovering these hidden cost-saving opportunities lies in your business software. Indeed, the right software may offer you cost-saving opportunities you didn’t even know existed.

Ready for a specialized food ERP?

Learn more about Aptean Food & Beverage ERP JustFood Edition — a solution purpose-built to solve your challenges and propel your food business and digital transformation to the next level.